Yunnan Province is located in the Yunnan-Guizhou Plateau at low latitudes. Due to its special geographical conditions and climate, Yunnan flowers are colorful and easy to obtain high-quality flowers. However, the strong sunlight burns the leaves of some flowers and crops, which affects their growth and quality, thus losing their commercial value. In particular, the phenomenon of blackening of petals and lighter color caused by burns is more serious in the planting and production of red rose roses. In view of this phenomenon, we developed the functional greenhouse film with high light transmission and astigmatism in Yunnan.

The functional film with high light transmission, high scattering, high heat preservation, and super long life self-cleaning will be used as the fifth generation functional agricultural film in China, in order to improve the serious uneven distribution of light within the vegetable population and greatly increase the production capacity of vegetable facilities. effectively prevent sunburn of vegetables, weaken phototaxis, and improve the quality of stem and leaf vegetables.

1 Experimental part 1.1 main raw materials.

Low-density polyethylene LDPE:2130,MFR 0.3g/10min, Iran petrochemical.

Low-density polyethylene LDPE:2426H,MFR 2.0g/10min, Lanzhou Petrochemical.

Linear low-density polyethylene LLDPE: 9047 Permian 1.0g/10min, Daqing Petrochemical Co., Ltd.

Metallocene polyethylene m-LLDPE: 2010 MEJ MFR 1.0g/10min, ExxonMobil, USA.

Light diffusion agent (silicone): WD-102, Wanda Chemical Co., Limited.

Light stabilizer: HS-944: Beijing Tiangang Auxiliaries Co., Ltd.

Antioxidant: B215: Beijing Yanlian Co., Ltd.

1.2 production equipment and testing instruments.

Rotary claw refiner granulator, Hangzhou Lin’an Luyuan Fine Chemicals Co., Ltd.

Twin Screw Extruder granulator CJWA75-48D, Changzhou Jinwei Chemical equipment Co., Ltd.

Mixer, Zhenxin machinery.

Three-layer composite blow molding greenhouse film machine M3N-10000, Guangdong Jinming equipment Co., Ltd.

Electronic universal testing machine CMT2202, Meters Industrial Systems (China) Co., Ltd.

Illuminance meter 1339, Taishi Electronic Industry Co., Ltd. Light transmittance / haze tester WGT-S, Shanghai Shenguang instrument Co., Ltd.

1.3 preparation of astigmatism masterbatch and longevity masterbatch.

Preparation of astigmatism masterbatch: a certain proportion of astigmatism agent KS-1500 and antioxidant B215 LLDPE2426H resin were weighed by electronic scale according to the design formula, mixed evenly in a mixing pot, then heated, plasticized and extruded in a twin-screw extruder, and the astigmatism masterbatch was obtained after drawing and water cooling. Preparation of longevity masterbatch: a certain proportion of light stabilizer HS-944 and antioxidant B215 LLDPE 2426H resin were weighed by electronic scale according to the design formula, added to the rotary claw internal mixer for heating, plasticizing and mixing, and then extruded in a single screw extruder, the longevity masterbatch was obtained by drawing water cooling and granulation.

1.4 production of greenhouse film with high transmission and astigmatism function.

First of all, LDPE 2130m LLDPE 9047 LLDPE 2010ME, astigmatism masterbatch, longevity masterbatch and other raw materials are divided into inner layer, middle layer and outer layer according to different proportions to mix evenly, then the mixed raw materials are added to the corresponding inner, middle and outer extruder for blowing film, and then after traction, cutter and rewinding, the finished product is obtained.

1.5 performance testing.

The light transmittance and haze were measured by light transmittance haze tester. Test the light intensity with an illuminance meter. The mechanical properties of the products are tested by an electronic universal testing machine.

2 results.

2.1 Test and analysis of mechanical properties.

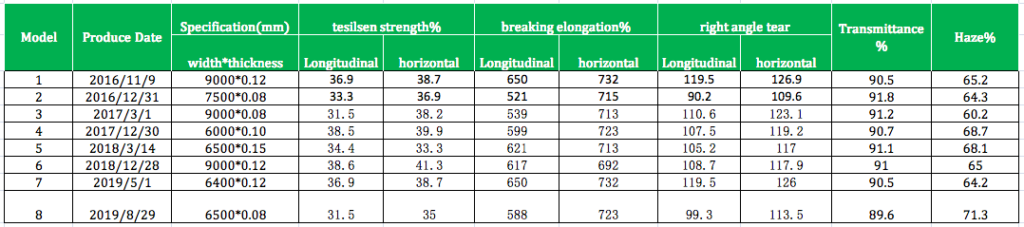

From the test results of the mechanical properties of some astigmatism greenhouse films produced in recent 3 years in Table 1, the addition of light diffuser (organosilicon): KS-1500 has little effect on the mechanical properties of the greenhouse films, and the mechanical indexes of the products meet the requirements of the national standard GB4455- 2006.

2.2 Detection and analysis of light transmittance and haze.

Light transmittance and haze are important indicators to characterize the optical properties of greenhouse films. Light transmittance is expressed as a percentage of the ratio of the luminous flux of the material to the luminous flux of the incident light, and is the unclear degree of the transparent or translucent material. It is the cloudy or cloudy appearance of the interior or surface of the material caused by light scattering, expressed as a percentage of the ratio of the scattered luminous flux to the luminous flux passing through the material [2]. The higher the light transmittance and the higher the fog value, the more light passing through the greenhouse film, the more scattered light, and the softer scattered light, which can create a milder microclimate environment for plants, which is characterized by the reduction of scorch and burns of crop leaves. make crops grow and develop better, increase yield and improve quality.

According to the test results of light transmittance and haze of some astigmatic greenhouse films produced in recent 3 years in Table 1, by adding silicone astigmatism agent to produce greenhouse film with thickness 0.08~0.12mm, adjusting the addition ratio of astigmatism masterbatch, and according to the different needs of customers or crops, without reducing the light transmittance of the product, we can produce high light transmittance and high haze astigmatism greenhouse film with high light transmittance and high haze, and the light transmittance is 89% / 92%. The fog value is 60% “80%, while the light transmittance of ordinary greenhouse film products is 89%” 91%, and the fog value is 14% “25%.

In the national standard GB4455-2006 “Agricultural Polyethylene blown greenhouse Film”, the light transmittance of transparent polyethylene anti-aging greenhouse film is ≥ 85%. The high transmittance and astigmatism function greenhouse film produced by the company meets the requirements of the national standard.

| The thickness(mm) &haze(%) | Light intensity in sunlight/LUX | Light intensity under film/LUX | Percentage of decrease in light intensity % | |

| light diffusion film1 | 0.08mm ; 60% | 80 034 | 68 512 | -14.4 |

| light diffusion film2 | 0.08mm ; 70% | 81 316 | 62 688 | -22.9 |

| light diffusion film3 | 0.10mm ; 60% | 80 038 | 69 942 | -12.6 |

| common film | 0.08mm ; 19% | 78 222 | 73 064 | -6.6 |

As can be seen from Table 2, due to the diffuse scattering of sunlight through the astigmatic film, the scattering of scattered light is the same as the absorption of light, and the scattering of light weakens the intensity of light passing through the substance. The sunlight intensity of the ordinary greenhouse film can be reduced by 6% to 7%, while the astigmatism greenhouse film can be reduced by 12% to 23%, and the greater the haze value is, the more scattered light is, the more the light intensity under the film is reduced, and the lower the light intensity is.

2.4 effect of astigmatism greenhouse film on temperature in the greenhouse.

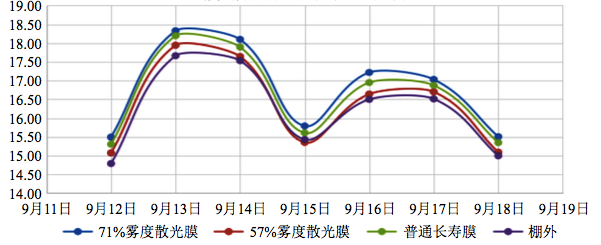

Figure 1, figure 2 show the field application temperature test of astigmatism greenhouse film. It can be seen that the temperature of astigmatism greenhouse film is 1 ~ 2 °C lower than that of ordinary greenhouse film during the day, which can avoid high-temperature burn of crops in the greenhouse during the day. At the same time, the astigmatism greenhouse film has the common heat preservation property of the greenhouse film at night.

2.5 Application of astigmatism greenhouse film.

According to the application of astigmatism greenhouse film produced in recent 3 years, astigmatism greenhouse film has been applied to many kinds of vegetables, fruits and flowers, such as tomato, cucumber, pepper, grape, sugar orange, hydrangea, rose and so on. Astigmatism film can increase crop yield and improve product quality in tomato, cucumber, pepper and other vegetables while planting sugar orange can reduce fruit drop rate and prolong fruit harvest. In the planting of hydrangea and roses, it can effectively prevent excessive sunlight and high temperature in the shed from burning petals and leaves, or causing petals to fade. Light stabilizers and antioxidants have been added to the production of astigmatism greenhouse film, and its service life can reach 2 to 3 years. The production of astigmatism greenhouse film has good social and economic benefits. Of course, in practical application, astigmatism greenhouse films with different haze values should be selected according to the local climate and different crops.

3 conclusion.

The main results are as follows: 1) the self-made masterbatch of silicone light diffuser is added to the greenhouse film to produce the functional greenhouse film with high light transmittance and high astigmatism.

2) functional greenhouse films with different astigmatism (haze) can be produced by adjusting the addition ratio of light diffusion masterbatch.

3) Light stabilizers and antioxidants have been added in the production of astigmatism greenhouse film, and its service life can reach 2 to 3 years.

4) the application of astigmatism greenhouse film can reduce the light intensity and daytime temperature in the greenhouse, evenly distribute the light in the greenhouse, increase the light area of plants, provide soft light and good growth environment for crop growth, increase crop yield, improve quality, prolong harvest time, and effectively reduce the burns of petals and leaves caused by excessive sunlight and high temperature in the greenhouse for flower planting. Or cause the petals to fade.