Silicone microsphere is a kind of ultra-fine spherical powder material with organic and inorganic characteristics, three-dimensional reticulated spherical shape, good optical properties, dispersibility, lubricity, heat resistance, excellent silky feel and so on.

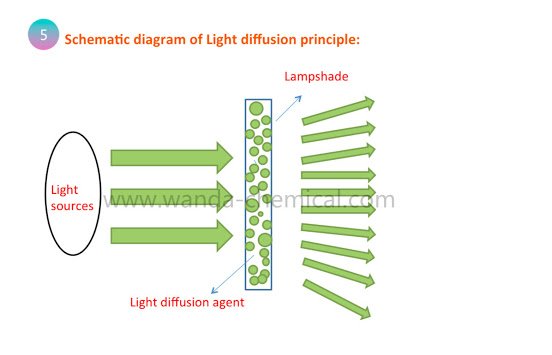

As a light diffusion agent, silicone microspheres are widely used in LED lampshades and bulb injection molding materials, which make the light source scatter and produce soft light. The main factors affecting the effectiveness of its use are as follows:

- ) Particle size.

- ) Spherical regularity.

- ) The shape of the material itself.

- ) Refractive index of material.

- ) Material thickness, etc.

- Particle size.

Under the condition of the same materials and the same amount of silicone microsphere light diffusion agent, the smaller the particle size of the silicone microsphere is, the more the number of particles is, the more times the light is deflected, the greater the diffusivity is, and the higher the haze is. In other words, if you want to get the same haze, the addition proportion of light diffusion particles in silicone microspheres can be reduced and the cost can be saved. However, the more the number of light diffusion particles in silicone microspheres, the lower the light transmittance. Therefore, it is necessary to determine the additional amount of light diffuser according to the change of haze and light transmittance according to the different particle sizes of the light diffuser.

2. The refractive index of the material itself.

Haze is the diffusivity caused by the deflection of light passing through the interface of two different refractive index materials. Therefore, the greater the difference of refractive index between materials, the greater the deflection angle of light passing through, the higher the efficiency of haze.

For example, the refractive index of PS and PC is 1.59, the refractive index of PMMA is 1.49, and that of silicone microspheres is 1.42 to 1.45, so the amount of silicone microsphere light diffuser needed to achieve the same haze of PS and PC is much less than that of PMMA. This is also the reason why the addition amount of PMMA light diffuser is 2-3 times higher than that of silicone microspheres.

3. Pahickness and morphology of materials.

The light diffusion materials sold on the market mainly have two forms: lamp board and ball bulb, in which the lamp board is routinely divided into 1mm, 1.5mm, and 2mm thickness, although the materials may all be the same, but the additional amount and particle size of silicone microsphere light diffuser are not the same.

In the case of standard 2 micron silicone microsphere light diffusion particles, under the condition of a certain amount of addition, the 1mm light diffusion plate is closely arranged in the thickness direction, and it is impossible to exceed 1000 microns / 2 microns = 500silicone microsphere light diffusion particles, and the particles also need to be bonded between the material itself, while the diffuser plates of 1.5mm and 2mm are arranged with a maximum of 750 and 1000 silicone microsphere light diffusion particles, so by comparison. There is a deviation between haze and light transmittance, so it is necessary to synthesize haze and transmittance to determine the appropriate amount of silicone microsphere light diffuser, or to use smaller size silicone microsphere light diffusion particles to make up for the amount of light deflection. for example, the board with 1mm thickness prepared by 1.5um silicone microsphere light diffusion particles can also achieve good haze.

However, as far as the production of ball bulbs is concerned, because the lamp beads are far away from the lampshade, the requirements for haze will be reduced. In addition, because of its large light reflection area and strong reflection ability, the light loss is very low, so the light transmittance is high. Therefore, a relatively small amount of addition can achieve better light transmittance and haze, generally adding 0.3% to 0.5% of PC materials.

4. Spherical regularity of Light Diffusion particles in silicone Microspheres.

The more true spherical silicone microsphere light diffuser particles are, the more times the light deflects on the sphere surface, and the reflection angle is more regular, so the prepared light diffusion material has higher haze, better application effect, and lower addition.

What is the advantage of the organic silicone microspheres compared to PMMA light diffusing particles?

The refractive index of PS and PC is 1.59. Because the refractive index of the PMMA microsphere is higher than that of the silicone microsphere, the amount of PMMA silicone microsphere light diffuser needed to achieve the same haze is much higher than that of silicone microsphere, and the cost is high.

The heat resistance of l PMMA light diffusion particles is poor, because the main chain of silicone microspheres is Si-O-Si, while the main chain of PMMA microspheres is Cmurc and Cmurm. The bond energy of Omuri Si is about 30% higher than that of Cmurc and Cmuro, so the heat resistance of the organosilicon microsphere light diffuser is better.

L-PMMA has a short service life and is easy to yellowing because PMMA is polymerized by double-bond free radicals, so the surface of the microsphere will remain double bonds, which is easy to be oxidized at high temperature or for a long time, thus yellowing and affecting the effect of use.

The synthesis processes of the two are different, the particle size of silicone microspheres is better controlled, and the particle size distribution is narrower and more uniform.

For more information about light diffusion agent pls follow my updated news. any questions can leave a message in the comments or send me an email: [email protected]