In real life, there are many lamps and lanterns, such as street lamps, LED bulbs, LED fluorescent lamps, LED digital tubes, LED tunnel lights, LED street lights, LED ceiling lights, etc., all of which are made of light diffused PC raw materials. Because the light diffuser is spherical and uniformly dispersed in PC resin to form an island structure, due to the different refractive index of PC resin and light diffuser, the light on the surface of the light diffuser is similar to mirror reflection, and the light diffusion effect is achieved after multiple reflections.

The optical properties of the materials are determined by the amount of light diffusion agent, particle size and distribution, and refractive index. The indexes to evaluate the optical properties of light diffusion materials include full light transmittance, haze, and dispersion. The degree of dispersion refers to the angle at which the relative transmittance is 50%. How to achieve high transmittance and haze of astigmatic materials is difficult. The light from the fluorescent lamp shines around, and the light from behind is reflected back to the front, and the front light will be reflected if it exceeds the critical angle. Such light returns to the front through a variety of reflection processes. Other light from the diffuser plate will be refracted into the interior of the diffuser plate. To the inside of the diffusion plate, meet with the diffuser, reflect and astigmatism many times, and maintain a certain brightness of the surface in this process.

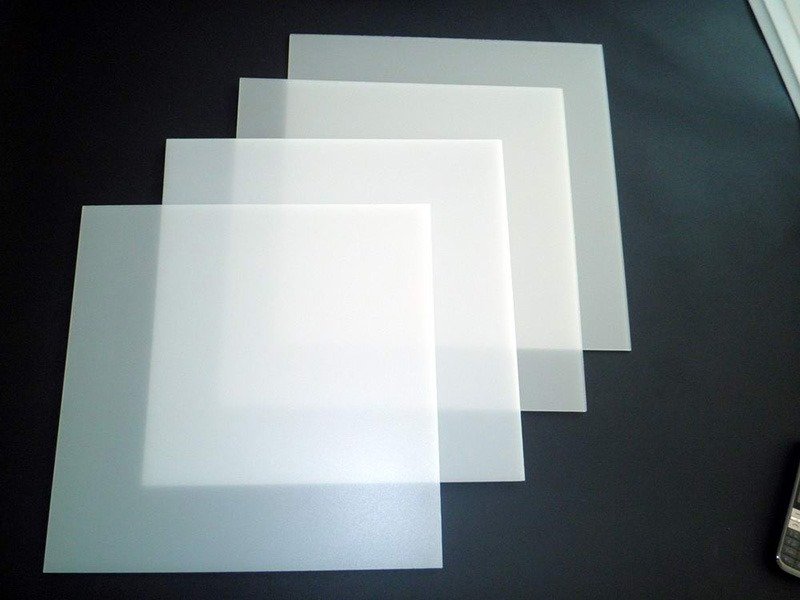

Light diffusion PC plastic, also called polycarbonate light diffusion plastic, It is a kind of transparent and opaque light diffusion material particles polymerized by a special process with transparent PC (polycarbonate) plastic as the base material and adding certain specific light diffuser and other auxiliaries.

The specific models of light diffusion PC raw materials are as follows:

| Japan Teijin PC | ML-1102; ML-1103; ML-3206; ML-3120; ML-3104 ;ML-4104; ML-4120; ML-5206.. |

| SABIC PC | FXD103;FXD141R;LUX2114; LUX2614; LUX9610; LUX9612; LUX9616… |

| Korea LG PC | LD7890; LD7850; LD7800; LD7700; LD7600….. |

| Japan Mitsubishi PC | EFD2110U; EFD2230U; DH-3002R….. |

| Janpan Idemitsu PC | LEV-1700; LZ2510V; LZ1710V; AZ1900T….. |

| Korea Samsung PC | PD-1010; FD-1112; FD-1102….. |

| Covestro AG | LED-2245; LED-2643; LED-5101 |

There are three kinds of light diffuser PC raw material solutions:

1.) Adding toner, such as barium sulfate, to the original lampshade, adding these particles can make light to refract multiple times to achieve the effect of light diffusion, the light diffusion effect of this method is not obvious, and seriously affect the light transmittance; the improvement of this scheme is to replace the opaque toner with a transparent light diffuser to reduce the loss of light transmittance, most manufacturers adopt this scheme.

2.) Increase the frosting effect, but the light diffusion effect is limited, and the emitted light is not uniform and soft; this scheme requires very high surface frosting texture control, and the sand grain uniformity directly affects the effect, and there are few manufacturers in the industry who can achieve extremely high sand grain uniformity.

3. ) Increase the prism, but the light diffusion effect is limited, and the dazzling LED lamp beads can still be seen; on the basis of this scheme, the PC light diffusion film and sheet with the unique surface structure are optimized to achieve higher light diffusion effect and uniformity, and the hiding power of LED lamp beads is also greatly enhanced.

What matters should be paid attention to in the production of optical diffusion PC ?

1.) selection of optical diffuser and mixing process.

I believe that people in the plastic industry are well aware that light diffusion agent not only has a decisive impact on the effect of light diffusion PC, but also affects the cost of light diffusion PC, so how much silicone is added is a question. At present, a new optical diffuser of PMMA microspheres on the market can solve the yellowing problem of light diffusion PC to the greatest extent, and the price is low, which can effectively reduce the production cost.

2.) Cleaning the machine is the key.

The key to processing is to clean the machine thoroughly. If the machine is not clean, the light diffusion PC will turn yellow and lose its original value. So how to clean it before it is clean? First of all, use the nozzle to pass the machine, and then use transparent particles to pass the machine, so that the machine is clean.

3.) the formula of light diffuser PC.

The formula of light diffusion PC is the secret of every company, and each company has its own method of producing light diffusion, which need not be discussed too much.

4.) the light transmittance reaches 85%.

Now the light diffusion PC will require a light transmittance of 85%, and must be weather-resistant. If this requirement is not met, it will have an impact on the lamp factories that use it as raw materials, and affect the quality and brand of their products.

For more information or question you can make comments or leave a message to my email: [email protected]