1 preface.

As the fourth generation, light source, light-emitting diode (LED) has a series of advantages, such as low energy consumption, small size, fast response, high reliability, long life and so on.

In recent years, driven by the development concept of energy saving and environmental protection, LED lighting has ushered in rapid development, replacing the traditional lighting source, and has been widely used in display, lighting, signal indication and other fields. However, the heat of LED light sources is serious, so it puts forward higher requirements for the heat resistance of peripheral materials such as lampshades and lamp holders. Polycarbonate (PC) material has excellent optical properties, mechanical properties, heat resistance and dielectric properties, so it is an ideal material for making LED lamps and lanterns. Because of the high luminous efficiency and strong directivity, the light source composed of LED lamp beads and its array is strong, which is easy to cause damage to human eyes, so it is necessary to use light diffusion material as the front cover of LED light source to transform it into a more uniform and soft surface light source. Light diffusion materials are generally prepared by dispersing light diffuser particles in a transparent polymer matrix and have high light transmittance and haze, which can achieve a good leveling effect under the condition of small light intensity loss [3]. Polystyrene, polymethyl methacrylate and silica are commonly used in photodiffusion PC materials, but the application range of these materials is limited to some extent because of their relatively high cost. In this paper, the effect of boehmite on the performance of PC is studied. The results show that boehmite can not only maintain the excellent mechanical properties of PC, but also provide good light diffusion effect and processing fluidity, which is expected to provide a more cost-effective solution for the large-scale LED lighting equipment.

2. Experiment Part

2.1 main raw materials and equipment.

PC resin: industrial grade, melt flow rate is 3 g 10 min, Mitsubishi Co., Ltd.; Boehmite: particle size 2 μ m, Anhui Yishitong Co., Ltd. Other auxiliaries: on the market. Twin Screw Extruder: STS-35, Nanjing Kobelong Machinery Co., Ltd.; injection Molding Machine: HTF86/TJ, China Haitian plastic Machinery Co., Ltd.; Universal testing Machine: CMT6103, Shenzhen New Sansi material testing Co., Ltd.; impact tester: BPI-5.5STAC, Zwick/Roell, Germany; melt flow rate tester: BMF-003, Zwick/Roell of Germany; visible light transmittance meter: BTR-1S, Hebei Xianhe Science and Technology Co., Ltd. Scanning Electron microscope: Smur3400N, Beijing Tianmei (China) Scientific Instruments Co., Ltd.

2.2 preparation of photodiffusion PC.

The experimental formula of photodiffusion PC is shown in Table 1. According to the formula, the components are fully mixed and added to the extruder hopper. The extrusion temperature from the first zone to the tenth zone is 140,270,270,260,260,250,250,250,270 °C, the screw speed is 300 r/min, and the feed is 30 kg/h. After the extrusion strip is sliced and dried, the mechanics and square plate are prepared by injection molding mechanism. The injection temperature is 300 °C, the injection pressure and speed are 800.144 MPa and 55% ~ 99%, respectively. After the splines were adjusted at 25 °C and 50% humidity for 24 h, the related tests were carried out.

| PC | Boehmite | |

| 1# | 100 | |

| 2# | 100 | 0.5 |

| 3# | 100 | 1 |

| 4# | 100 | 2 |

| 5# | 100 | 3 |

2.3 performance testing.

The light transmittance and haze were measured by a square plate with a thickness of 2.0 mm. The test condition of melting index is 300 °C 1.2kg. The mechanical properties are tested by ASTM test standard. The tensile test speed is 50 mm/min and the bending test speed is 2 mm/min.

Fig.1 Morphology of boehmite (a) and PC/boehmite (b)

3 results and discussion.

3.1 Effect of boehmite on the optical properties of PC

The composition of boehmite is γ-AlOOH and its crystal is white at room temperature. The morphology of boehmite is a cubic crystal with a particle size of about 2 μ m by SEM, and its shape and size are regular and uniform (Fig. 1a), which is the basis for its good optical effect. When boehmite is added to PC resin, it can be well dispersed, there is no large size aggregate, the number of light scattering particles in the system will not be reduced because of agglomeration, and due to the lack of interaction, the bond between boehmite and PC resin is weak, there is a certain gap between them (figure 1b), which also enhances the scattering effect of light at the interface [6].

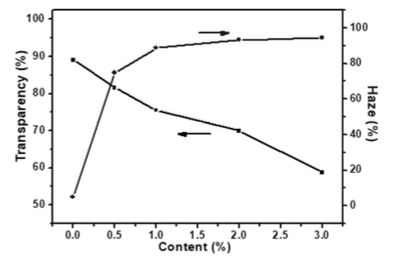

Transparency and haze of PC containing boehmite

The effect of boehmite on the light transmittance and haze of PC is shown in figure 2. With the increase of boehmite content, the light transmittance of PC decreased linearly. When the content of boehmite reached 3.0%, the light transmittance decreased from 89.1% of pure PC to 58.8%, which remained at a high level. The reason is that the refractive index of boehmite is 1.63 to 1.67, which is close to that of PC. In terms of haze, when the content of boehmite is 0.5%, the haze increases sharply from 5.0% of pure PC to 74.7%. When the content of boehmite is 2.0%, the haze is more than 90% (93.2%), but when the content is further increased to 3.0%, the haze only increases to 94.5%. The practical application of the corresponding products in this field is not significant.

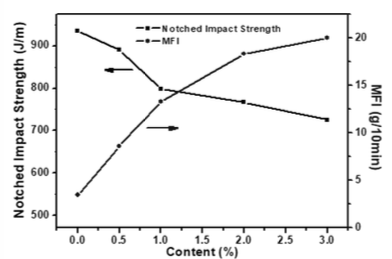

Fig.3 Flowability and toughness of PC containing boehmite

Fig.4

Strength and Stiffness of PC containing boehmite

In the molecular structure of PC, the stability of the carbonate bonds is poor. In the processing environment, boehmite as a kind of hydroxide can catalyze the hydrolysis of carbonate bonds, resulting in the decrease of molecular weight of PC. It can be seen from figure 3 that with the increase of boehmite content, the melting index of PC increases rapidly from 3.5 g 10 min to 20.0 g 10 min. In terms of toughness, the notched impact strength of PC was reduced from 935.7 Jago to 725.0 Jago with the addition of 3.0% boehmite, but it was still kept at a high level. Considering that the boehmite particles dispersed in PC are a defect point, which must have a negative effect on the impact strength, it is speculated that the decrease of molecular weight of PC and its effect on toughness are limited, and the substantial increase of fluidity of the system mainly depends on the plasticizing effect of low molecular weight products produced by hydrolysis on PC. On the other hand, boehmite can strengthen PC to a certain extent, and the bending strength and modulus of PC can be increased from 100.5 MPa and 2471 MPa to 106.5 MPa and 2701 MPa respectively with 3.0% addition (Fig. 4).

4 conclusion

The addition of boehmite to PC can effectively improve the haze and maintain a high light transmittance, thus achieving a good light diffusion effect; boehmite can enhance PC, but to a certain extent lead to the hydrolysis of carbonate bond and the decrease of molecular weight of PC, which greatly increases the fluidity and slightly reduces the toughness of PC. When the content of boehmite is 2.0%, the material properties are ideal in light diffusion effect, mechanical properties and processing fluidity, and have good comprehensive properties.