As a solid-state semiconductor device that directly converts electrical energy into light energy, light-emitting diode (Light Emitting Diode,LED) not only has a solid structure, shock resistance, fast light response, long life, but also have low energy consumption. It was used for lighting, in theory, only 10% of the energy consumption of incandescent lamps, compared with fluorescent lamps, LED can also achieve 50% energy saving effect. It was used in the display, it can not only save energy; but also make the device ultra-thin, lightweight and long life. Therefore, LED has become a real source of green lighting and display light, widely used in urban and household lighting, electronic appliances, automotive and other industries, and has been ubiquitous in modern society.

Light diffusion agent was added to transparent plastics such as PC, PMMA, PS and so on to obtain optical diffusion. Loose plastic can not only cover the light source and dazzling light but also make the whole transparent resin hair. Produce softer, more beautiful and elegant light to achieve the comfortable effect of transparent and opaque light.

PC has excellent light transmittance (light transmittance up to 89%), good mechanical properties, insulation properties, flame retardant and anti-aging properties, so it is the preferred substrate for LED light scattering materials. therefore, PC-based light diffusion materials have attracted wide attention. we added cross-linking PMMA microsphere light diffuser to PC, studied the light diffusion mechanism of PC light diffusion plate and the effect of particle size of light diffuser on the light transmittance, haze, effective light scattering coefficient and mechanical properties of PC light diffusion plate. The results show that the light transmittance of PC light diffusion plate is higher when the particle size of light diffuser is 20.0 μ m, the haze of PC light diffusion plate is larger when the particle size of light diffuser is 1.8um, when the particle size of light diffuser is 3.0um, the effective light scattering coefficient of PC light diffusion plate is larger and meets the requirements of mechanical energy, and the particle size of light diffuser increases, the light transmittance increases and the haze decreases.

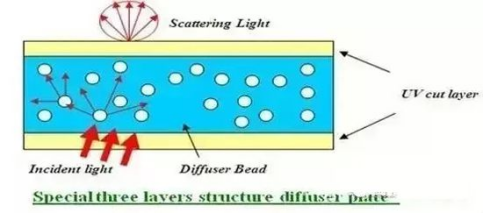

LED is a point light source. In practical applications, it is usually necessary to transform it into a line light source or a surface light source to make the light bright and soft. To achieve this transformation, it is inseparable from an indispensable light diffusion material. Light diffusion materials are generally composed of light diffusion agent and polymers, which are supplied to the market in the form of light diffusion plastics,light diffusion encapsulant, light diffusion coating and ink.

Light Diffusion Agent

At present, the light diffuser is made by special processing and surface treatment. The particle size is generally between 1 μ m and 10 μ m, and the average particle size is about 2 μ m. The beads have the function of astigmatism, good fluidity and good compatibility with optical resin substrate.

At present, optical diffuser is mainly divided into inorganic type and organic type. Inorganic light diffusers mainly include inorganic particles such as silicon dioxide, titanium dioxide, calcium carbonate, aluminum hydroxide and glass beads, while organic light diffusers mainly include cross-linked polystyrene, polymethacrylate and other organic polymer microspheres. Although inorganic particles have good heat resistance, they have some disadvantages, such as different shape, large deviation of particle size, lack of uniform diffusivity of light, low light transmittance and so on. Cross-linked polystyrene and polymethacrylate microspheres have good shape uniformity, controllable particle size deviation, high light transmittance, but low heat resistance. During light diffusion polymer extrusion granulation and high-temperature injection molding or extrusion molding of light guide devices, polymer particles are prone to deformation, thus affecting the uniform diffusion of light. Moreover, the light resistance of the polystyrene light diffuser is poor, and it is easy to yellowing, which affects the service quality and service life of LED.

Organic-inorganic hybrid organosilicon microsphere light diffuser has been developed in recent years. Silicone microsphere light diffusion agent not only has the characteristics of high heat resistance, light resistance and aging resistance of inorganic particles, but also has the characteristics of homogeneity of organic particle shape, high light transmittance, and good light diffusion uniformity, and its refractive index can be changed with the change of synthetic monomers, and the surface of the particles can be modified in situ by light diffusion. It has a broad application prospect to improve the compatibility and adaptability of light diffusion particles with polycarbonate (PC), polymethyl methacrylate (PMMA), polystyrene (PS) and other light guide plate matrix resins. Therefore, silicone microspheres are expected to be used as high-performance optical diffusers for LED.

Silicone light diffusion agent is usually a microsphere product formed by hydrolysis, condensation and cross-linking reaction of methyl trimethoxysilane and phenyl trimethoxysilane. The particle size distribution is between 1 μ m and 8 μ m, and the average particle size is 2 μ m. In recent years, silicone multinational companies in the United States, Japan and Germany have launched different types of silicone optical diffuser products.

Our technical use silicone microspheres were synthesized by hydrolysis-condensation method using dichlorodimethylsilane (DMDCS) and ethyl orthosilicate (TEOS) as monomers. The effects of monomer ratio, monomer concentration, and coupling agent on the morphology of the products were discussed, and the hydrophobicity and heat resistance of the products were further characterized. The experimental results show that the monomer ratio, monomer concentration and the use of silane coupling agent have important effects on the reaction process and the particle morphology of the product, the product has excellent thermal stability, and the mass heat loss rate is only 10.5% at 600 °C. the product also has high hydrophobicity and the static contact angle is 138.6 °.

How’s the dosage ratio and particle size of light diffusion agent affect the effect of light diffuser?

Light diffusion agent was added to transparent plastics such as PC, PMMA, PS and so on to obtain optical diffusion.

Loose plastic can not only cover the light source and dazzling light, but also make the whole transparent resin softer, more beautiful and elegant light to achieve the comfortable effect of transparent and opaque light.

PC has excellent light transmittance (light transmittance up to 89%), good mechanical properties, insulation properties, flame retardant and anti-aging properties, so it is the preferred substrate for LED light scattering materials. therefore, PC-based light diffusion materials have attracted wide attention. we added cross-linking PMMA microsphere light diffuser to PC, researching the light diffusion mechanism of PC light diffusion plate and the effect of particle size of light diffuser on the light transmittance, haze, effective light scattering coefficient and mechanical properties of PC light diffusion plate. The results show that the light transmittance of PC light diffusion plate is higher when the particle size of light diffuser is 2.0μ m, the haze of PC light diffusion plate is larger when the particle size of light diffuser is 1.8um, when the particle size of light diffuser is 3.0um, the effective light scattering coefficient of PC light diffusion plate is larger and meets the requirements of mechanical energy, and the particle size of light diffuser increases, the light transmittance increases and the haze decreases.

After mixing acrylic acid, silicone light diffusion and other auxiliaries, the light diffusion PC was prepared by parallel twin screw extruder. The effects of different ratios of acrylic acid and silicone light diffusion agent on the optical properties of PC were studied. The results show that the light diffusion PC with different optical properties can be obtained by adding a different dosage of acrylic acid and silicone light diffusion agent. Using PC as substrate, acrylic resin and silicone resin as silicone diffuser, it is found that the addition of silicone light diffusion agent has no effect on the tensile strength of PC-based light diffuser, but it has a certain effect on the notched impact strength. The particle size of light diffusion agent has an effect on the haze of PC-based light diffusion materials in a certain range, and the haze is slightly higher when the particle size is larger. The amount of light diffuser has a great influence on the light transmittance and haze of PC-based light diffusion materials. When 0.3 wt% organosilicon light diffuser C is added, the effective light diffusion coefficient, transmittance and haze of PC-based light diffusion materials are 76.7%, 80.8% and 94.9%, respectively.

Using PC powder, silicone light diffusion agent and YAG:Ce fluorescent powder as raw materials, PC/YAG: ce light diffusion agent fluorescent resin samples with a different mass fraction of organosilicon light diffusion agent were prepared by melt blending, high-temperature pressing, and thinning polishing process. the results show that the fluorescent resin samples have high light transmittance in the spectral range of 500 to 800 nm. The main phase of the sample is Y3A15O12 and there are two excitation peaks at 342and 448nm. The emission spectrum has a wide peak at 532 nm, which belongs to the 5d 4f transition emission of Ce3+, and the corresponding fluorescence lifetime is about 61.5 ns. The luminous efficiency of the fluorescent resin sample applied to the packaging of white LED devices is 81.12 Lm/W/100 mA, indicating that the PC/YAG:Ce photoluminescent resin sheet is suitable for a new type of fluorescent material for white LED packaging.

Using optical grade PMMA as substrate, different proportions of spherical silica light diffusion agent An and B were added to study the effects of optical diffuser content, spherical particle size and particle size distribution on the light transmittance, haze and mechanical properties of the material. The results show that good light diffusion materials can be obtained by adding spherical silica light diffusion agent to PMMA. When the average particle size is 2 μ m and the mass fraction is 0.4%, the light transmittance of the sample is 88.0%, the haze is 90.1%, and the effective light diffusion coefficient is 79.3%, which is the highest among the known organic light diffusers. It can not only obviously increase the tensile strength of PMMA, but also has little effect on the bending strength and notched impact strength, so it has a good practical application value. We used twin-screw extrusion mixing and injection molding to prepare light diffusion plates based on PMMA with different light diffuser content and surface addition of micro-structure. The effect of optical diffuser and microstructure on the optical properties of optical diffusion plate is introduced. The light diffuser can reduce the transmittance and improve the haze. Without adding microstructure, when the mass fraction of the light diffuser is 0.8%, the penetration of the sample is 87.97%, the haze is 94.45%, and the diffusion effect is better. When the content of light diffuser is low, the haze of the light diffusion plate is greatly increased and the transmittance decreases very little.

The PET light diffusion film was prepared by adding light diffuser to polyethylene terephthalate (PET) by blending. The effects of refractive index and particle size of light diffuser particles on light diffusion are calculated by using Mie scattering theory, and the theoretical calculation results are verified by experiments. The results show that the refractive index of light diffusion agent particles has little effect on the effect of light diffusion, but the influence of particle size is greater, which is consistent with the theoretical calculation results. The effect and reason of the amount of light diffuser on the light diffusion effect were discussed, and the PET light diffusion film with light transmittance of 85.3% and haze of 90.86% was prepared.

In a words, the bigger particle size of light diffusion agent is, the better transmittance is, while the haze will be down ; more dosage ratio of light diffusion agent is, the smaller transiittance is , while the haze will be better accordly. the refractive index of light diffusion agent particles has little effect on the effect of light diffusion, but the influence of particle size is greater, but in practical application, it is depend on your raw matrials, thinckness and details requirements.

Should you have any questions or help welcome to leave a message in the comments or send my email: [email protected]