Introduction

In a world where technology and innovation intersect, materials like silicone resin powder have emerged as silent revolutionaries. You might not realize it, but this fine, unassuming powder plays a pivotal role in numerous products and industries we interact with daily. From the sleek smartphone in your pocket to the high-performance automotive parts in your car, silicone resin powder is a key ingredient that enhances durability, functionality, and design. But what exactly is this material, and why has it become so indispensable in modern manufacturing and design? In this comprehensive guide, we’ll delve into the fascinating world of silicone resin powder, uncovering its properties, applications, and the reasons behind its widespread popularity. Whether you’re a curious consumer, a seasoned industry professional, or somewhere in between, prepare to discover how this remarkable material shapes our world in ways you might never have imagined.

II. What is Silicone Resin Powder?

Silicone resin powder, at its core, is a fine, granular form of silicone resin, a polymer known for its remarkable stability and resilience. This material is synthesized through a complex chemical process, where siloxane, a compound made of silicon, oxygen, carbon, and hydrogen, undergoes polymerization. The result is a versatile, high-performance material that combines the best qualities of organic and inorganic substances.

But what sets silicone resin powder apart from other materials? The answer lies in its unique molecular structure. Silicone resins are characterized by their Si-O-Si (silicon-oxygen-silicon) backbone, which imparts exceptional thermal stability and chemical resistance. Unlike many organic polymers that degrade under intense heat or harsh chemical environments, silicone resin powder maintains its integrity, making it an ideal choice for applications requiring long-term durability and reliability.

Moreover, silicone resin powder is known for its excellent electrical insulation properties. This characteristic is crucial in the electronics industry, where materials must prevent electrical leakage and withstand various environmental stresses without compromising performance. The powder’s insulating properties are complemented by its ability to repel water and resist moisture, further enhancing its suitability for electronic applications.

The versatility of silicone resin powder extends beyond its physical and chemical properties. It can be engineered to exhibit various degrees of hardness, flexibility, and transparency, allowing for a wide range of applications. From rigid coatings that protect automotive parts from wear and tear to flexible molds used in crafting and baking, the applications of silicone resin powder are as diverse as they are innovative.

In summary, silicone resin powder is more than just a substance; it’s a testament to human ingenuity in material science. Its unique combination of stability, resilience, and versatility makes it a hidden hero in many of the products and technologies we rely on every day.

III. The Science Behind Silicone Resin Powder

Delving deeper into the science of silicone resin powder reveals why it’s such a sought-after material in various industries. The key to its impressive attributes lies in its molecular architecture. Silicone, a polymer consisting of alternating silicon and oxygen atoms, is known for its high thermal stability and flexibility. This stability is primarily due to the strong Si-O bond, which is much stronger than the C-C bond found in organic polymers. This molecular robustness enables silicone resin powder to withstand extreme temperatures and environmental conditions without degrading.

Another scientific marvel of silicone resin powder is its hydrophobic nature. The non-polar silicon-oxygen backbone of the polymer repels water, making it an excellent water-resistant material. This property is particularly beneficial in coatings and sealants, where moisture resistance is crucial for durability and longevity.

Furthermore, silicone resin powder exhibits unique rheological properties. It can flow under stress, making it easy to process and mold, yet it retains its shape and strength once the stress is removed. This thixotropic behavior is a boon in applications like adhesives and coatings, where ease of application is as important as the performance of the final product.

The powder’s low thermal conductivity is another notable feature. It acts as an effective insulator, keeping heat in or out, depending on the application. This characteristic is particularly valuable in the electronics industry, where managing heat generation and dissipation is vital for device performance and longevity.

Lastly, the ability to modify the surface properties of silicone resin powder adds to its versatility. By altering the surface chemistry, manufacturers can produce powders with specific characteristics, such as increased adhesion, altered refractive index, or enhanced compatibility with other materials. This customization opens up a world of possibilities for innovative applications across various sectors.

In essence, the science behind silicone resin powder is a fascinating blend of chemistry and physics, resulting in a material that’s not only versatile and durable but also indispensable in modern technology and manufacturing.

IV. Manufacturing Process of Silicone Resin Powder

The journey from raw materials to versatile silicone resin powder involves a series of intricate chemical processes. Understanding this manufacturing process not only highlights the complexity behind this seemingly simple material but also underscores the technological advancements that make its production possible.

Synthesis of Basic Silicone Resin: The process begins with the synthesis of basic silicone resin, a task achieved by hydrolyzing and condensing organosilicon compounds. This step typically involves reacting silanes or siloxanes with water, leading to the formation of silanol groups. These groups then condense to form the silicone resin’s distinctive Si-O-Si backbone.

Polymerization and Curing: Once the basic resin is formed, it undergoes further polymerization and curing processes. These steps are crucial in determining the final properties of the silicone resin, such as its hardness, flexibility, and thermal stability. The conditions under which polymerization and curing occur, including temperature, pressure, and the presence of catalysts, are meticulously controlled to achieve the desired characteristics.

Grinding and Milling: After curing, the solid silicone resin is ground into a fine powder. This is where precision engineering comes into play. The particle size of the powder can significantly affect its behavior in subsequent applications. Therefore, the grinding and milling process is carefully monitored to ensure that the particle size distribution meets specific requirements.

Surface Modification: In some cases, the surface of the silicone resin powder is modified to enhance its performance in certain applications. This modification can involve coating the particles with other materials or chemically altering their surface properties. Such modifications can improve the powder’s dispersibility, compatibility with other substances, or functional characteristics.

Quality Control and Packaging: The final step in the manufacturing process is stringent quality control. The powder is tested for various properties, including particle size, purity, and consistency, to ensure it meets the required standards. Once approved, it is packaged and prepared for shipment to various industries and applications.

The manufacturing process of silicone resin powder is a testament to the advancements in chemical engineering and material science. It’s a process that transforms basic raw materials into a high-performance product that plays a critical role in numerous applications across the globe.

V. Key Applications and Uses

Silicone resin powder, with its unique set of properties, finds applications in a multitude of industries. Its versatility allows it to be a crucial component in various products, ranging from everyday items to specialized industrial applications.

.

Electronics and Electrical Components: In the electronics industry, silicone resin powder is used for its excellent insulating properties and thermal stability. It’s commonly found in encapsulants and coatings for electronic components, where it protects against moisture, dust, and temperature fluctuations.

.

Automotive Industry: The automotive sector utilizes silicone resin powder in the production of durable, heat-resistant parts. It’s used in under-the-hood components, sealants, and coatings, contributing to the longevity and performance of vehicles.

.

Cosmetics and Personal Care: In the world of cosmetics, silicone resin powder is prized for its ability to improve the texture and longevity of products. It’s a common ingredient in makeup, skincare, and hair care products, where it provides a silky, smooth feel and helps with the even distribution of pigments.

Aerospace and Aviation: The aerospace industry values silicone resin powder for its resistance to extreme temperatures and environmental conditions. It’s used in coatings, sealants, and adhesives, ensuring the reliability and safety of aerospace components.

.

Construction and Building: Silicone resin powder is also a key player in the construction industry. It’s used in paints, coatings, and sealants, providing weather resistance and durability to buildings and structures.

Medical Devices: In medical applications, silicone resin powder is used for its biocompatibility and stability. It’s found in coatings for medical devices, where it provides a protective, non-reactive layer.

.

Textile and Fabrics: The textile industry uses silicone resin powder to enhance the properties of fabrics. It’s used in coatings that impart water repellency, UV resistance, and improved durability to textiles.

.

3D Printing: With the rise of 3D printing technology, silicone resin powder has found a new application. It’s used in the production of 3D printing filaments, offering flexibility and heat resistance to printed objects.

.

Each of these applications showcases the adaptability of silicone resin powder, making it an invaluable material in the modern world. Its ability to enhance product performance, durability, and aesthetics is why it continues to be in high demand across various sectors.

VI. Benefits of Using Silicone Resin Powder

Silicone resin powder offers a plethora of benefits that make it a preferred choice in numerous applications. Understanding these advantages sheds light on why this material is so widely used and valued.

.

Durability and Longevity: One of the most significant benefits of silicone resin powder is its exceptional durability. It resists weathering, chemical degradation, and thermal breakdown, ensuring a long lifespan for products that incorporate it.

.

Thermal Stability: Silicone resin powder can withstand extreme temperatures, both high and low, without losing its structural integrity. This makes it ideal for applications in harsh thermal environments, such as automotive engine parts or aerospace components.

.

Electrical Insulation: With excellent dielectric properties, silicone resin powder is an effective insulator. This is crucial in the electronics industry, where it prevents electrical leaks and shorts in a wide range of devices.

.

Chemical Resistance: The powder is resistant to many chemicals, including oils, solvents, and acids. This resistance is vital in industrial applications where exposure to harsh chemicals is common.

.

Water Repellency: Its hydrophobic nature makes silicone resin powder an excellent material for water-resistant coatings. This property is particularly beneficial in outdoor applications and in the construction industry.

.

Flexibility and Versatility: The ability to tailor the properties of silicone resin powder during the manufacturing process makes it incredibly versatile. It can be engineered to be more or less flexible, harder or softer, and transparent or opaque, depending on the application’s needs.

.

Biocompatibility: In medical applications, the biocompatibility of silicone resin powder is a critical advantage. It does not react adversely with the human body, making it safe for use in medical devices and implants.

Ease of Application: In industries like construction and automotive, the ease of applying silicone-based coatings and sealants is a significant time and cost saver. The powder can be easily mixed and applied, forming a durable, protective layer.

These benefits collectively contribute to the widespread adoption of silicone resin powder in various industries. Its ability to enhance product performance, safety, and aesthetic appeal while ensuring environmental resistance and durability is unparalleled.

VII. Silicone Resin Powder in Everyday Life

While silicone resin powder is a staple in industrial applications, its presence in everyday life is often unnoticed yet equally significant. Here’s a glimpse into how this versatile material impacts our daily routines:

Home Appliances: Silicone resin powder is used in the coatings of various home appliances, providing heat resistance and electrical insulation. From toasters to coffee makers, it ensures safety and durability.

Personal Care Products: In the beauty industry, silicone resin powder enhances the texture and longevity of cosmetics. It’s a key ingredient in products like foundation, where it aids in smooth application and consistent coverage.

Textile Treatments: Your water-resistant jacket or UV-protected outdoor fabrics likely contain silicone resin powder. It’s used to treat textiles, offering protection against the elements and extending the life of the fabric.

Kitchenware: Silicone resin powder is used in non-stick coatings for cookware and in heat-resistant kitchen utensils. It makes cooking and baking safer and more convenient.

Automotive Care Products: In car polishes and waxes, silicone resin powder contributes to a glossy finish and helps protect the paint from weathering and UV damage.

Sealants and Adhesives: Around the house, silicone-based sealants and adhesives, containing silicone resin powder, are used for various DIY projects and repairs, thanks to their strong bonding properties and durability.

Electronics: Many of the electronic gadgets we use daily are protected by silicone resin coatings, which safeguard against moisture and thermal damage.

Medical Devices: Silicone resin powder is also present in the coatings of some medical devices, where its biocompatibility and stability are crucial.

This widespread use in everyday items underscores the integral role of silicone resin powder in enhancing the quality, safety, and functionality of products we rely on daily.

VIII. Challenges and Limitations

Despite its wide array of benefits and applications, silicone resin powder is not without its challenges and limitations. Understanding these helps in making informed decisions about its use and in driving future innovations.

Environmental Concerns: One of the primary challenges is the environmental impact of silicone production. The manufacturing process can be energy-intensive and may involve chemicals that need careful handling and disposal.

Cost Factors: Compared to some other materials, silicone resin powder can be more expensive. This cost factor can be a limitation for its use in cost-sensitive applications.

Processing Requirements: While silicone resin powder is versatile, it requires specific conditions for processing, such as controlled temperatures and pressures, which can add complexity to its use in manufacturing.

Compatibility Issues: In some applications, silicone resin may not be compatible with other materials, requiring additional treatment or the use of compatibilizers, which can complicate the manufacturing process.

Physical Limitations: While silicone resin is durable and resistant to many environmental factors, it may not be suitable for all applications, especially where extreme hardness or rigidity is required.

Addressing these challenges is crucial for the sustainable and efficient use of silicone resin powder. Ongoing research and development in the field aim to mitigate these limitations, ensuring that silicone resin continues to be a valuable material in various industries.

IX. Future Trends and Innovations

The future of silicone resin powder looks promising, with ongoing research and technological advancements poised to expand its applications and address current limitations. Here are some key trends and innovations in the field:

Eco-Friendly Production: Efforts are being made to make the production process of silicone resin powder more environmentally friendly. This includes reducing energy consumption, minimizing waste, and using greener raw materials.

Enhanced Properties: Research is focused on enhancing the physical and chemical properties of silicone resin powder. This includes increasing its thermal stability, mechanical strength, and compatibility with other materials.

Biomedical Applications: The biocompatibility of silicone resin powder opens up possibilities in the biomedical field. Innovations in drug delivery systems, implants, and prosthetics are areas of significant potential.

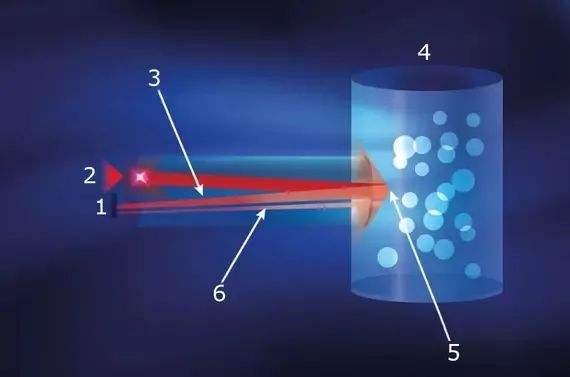

Electronics and Photonics: As the electronics industry evolves, there is a growing demand for materials with better insulating properties and thermal management. Silicone resin powder is being tailored for use in advanced electronics and photonic devices.

Sustainable Solutions: There is a trend towards developing silicone resins that are more sustainable and recyclable. This aligns with the global push for materials that support a circular economy.

Customization for Specific Applications: Tailoring silicone resin powders for specific applications is a growing trend. This includes developing grades with specific particle sizes, surface treatments, and functional additives for targeted applications.

These trends indicate a bright future for silicone resin powder, with potential breakthroughs that could open up new applications and markets, further solidifying its role as a key material in modern technology and manufacturing.

X. How to Choose the Right Silicone Resin Powder

Selecting the right silicone resin powder for a specific application can be a nuanced process, given the material’s diverse properties and uses. Here are some key considerations to guide you in making an informed choice:

Understand the Application Requirements: Clearly define what you need the silicone resin powder to achieve. Consider factors like temperature resistance, electrical properties, mechanical strength, and environmental resistance.

Particle Size and Distribution: The particle size and distribution can significantly affect the performance of the silicone resin powder in your application. Ensure that the powder’s specifications align with your needs, whether you require a fine powder for a smooth finish or a coarser grade for structural applications.

Compatibility with Other Materials: Check the compatibility of the silicone resin powder with other materials in your product or process. This includes considerations for adhesion, chemical reactivity, and the potential for any adverse interactions.

Certifications and Standards Compliance: For certain applications, especially in industries like aerospace, automotive, and medical, compliance with specific standards and certifications is crucial. Ensure that the silicone resin powder you choose meets these requirements.

Supplier Reputation and Quality Assurance: Choose a reputable supplier known for high-quality products. Look for suppliers who provide detailed product specifications, quality certifications, and technical support.

Cost-Effectiveness: While not compromising on quality and performance, consider the cost-effectiveness of the silicone resin powder. This includes not only the initial cost but also factors like processing requirements and longevity.

By carefully considering these factors, you can select a silicone resin powder that not only meets your application’s demands but also contributes to the overall success and efficiency of your product or process.

XI. Conclusion

Silicone resin powder, a marvel of modern material science, stands as a testament to human ingenuity and the relentless pursuit of innovation. Its journey from a laboratory curiosity to a cornerstone of numerous industries underscores its versatility and indispensability. From enhancing the durability of automotive parts to revolutionizing the cosmetics industry, silicone resin powder has proven its worth time and again.

As we’ve explored its properties, applications, and the challenges it faces, it’s clear that silicone resin powder is more than just a material; it’s a catalyst for progress, pushing the boundaries of what’s possible in manufacturing, technology, and design. Its future, bright with potential, promises further advancements and applications that will continue to shape our world in profound ways.

Whether you’re a seasoned industry professional, a curious learner, or someone fascinated by the wonders of material science, the story of silicone resin powder is a compelling reminder of how the right material can make all the difference in creating a better, more efficient, and more sustainable future.

XII. Call to Action

As we conclude our exploration of silicone resin powder, it’s clear that this material is not just a component of industrial processes but a key player in shaping the future of technology and innovation. Whether you’re involved in manufacturing, research, or product development, or simply have an interest in cutting-edge materials, the world of silicone resin powder offers a wealth of opportunities and insights.

We encourage you to delve deeper into this fascinating material. Consider its potential applications in your field, stay informed about the latest research and developments, and perhaps even think about how you can contribute to the next breakthrough in silicone resin technology.

If you found this guide informative and enlightening, we invite you to share it with your colleagues, peers, and anyone who might be interested in the remarkable world of silicone resin powder. Let’s spread the knowledge and inspire more innovation in this dynamic field.

Remember, the journey of discovery and application of materials like silicone resin powder is ongoing, and each one of us can play a part in shaping its path forward.