In order to prepare LED with high speed methyl acrylate (PMMA) microspheres as light diffuser in photodiode (LED) light source industry, the production of light diffusion materials must be continuous and polycarbonate (PC) light diffusion plates for high yield light sources must be realized, and the particle rates of light diffusers should be compared. Therefore, most of the new optical diffusion materials adopt the effect of transparent clustering diameter on the performance of PC optical diffusion plate. Preparation of composite matrix resin and photodiffusion microsphere particles by blending method.

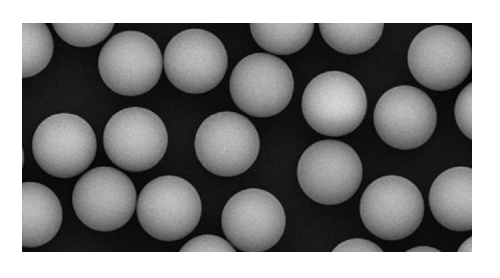

The light diffusion microspheres include inorganic particles, such as SiO2, BaSO4, and organic polymer microspheres, such as propanoic acid cross-linked microspheres, polyphenylene (PS), silicone resin and so on. However, due to the sharp surface of inorganic particles, it is easy to scratch the light diffusion material, resulting in its optical properties can be affected by shadow, so the organic polymer particles are widely used as light diffuser. The widely used cross-linked polymethyl group was used in this experiment.

1. 1 main raw material PC,1100, refractive index 1.59, Hunan petrochemical, Korea; MX system.

The light dispersant is a group of cross-linked P M M A microspheres with particle diameters of 1.8, 3.0, 10.0, 15.0 and 20.0 μ m, and the type numbers are respectively 1.8, 3.0, 10.0, 15.0 and 20.0 μ m.

1. 4 sexual ability tests.

According to GB/T 2410 Mel 2008, it is measured in the visible band.

The light transmittance (T t) and the light transmittance (T d) at which the light line deviates from the original incident light line 2.5 °, the haze is calculated to be TD / T t.

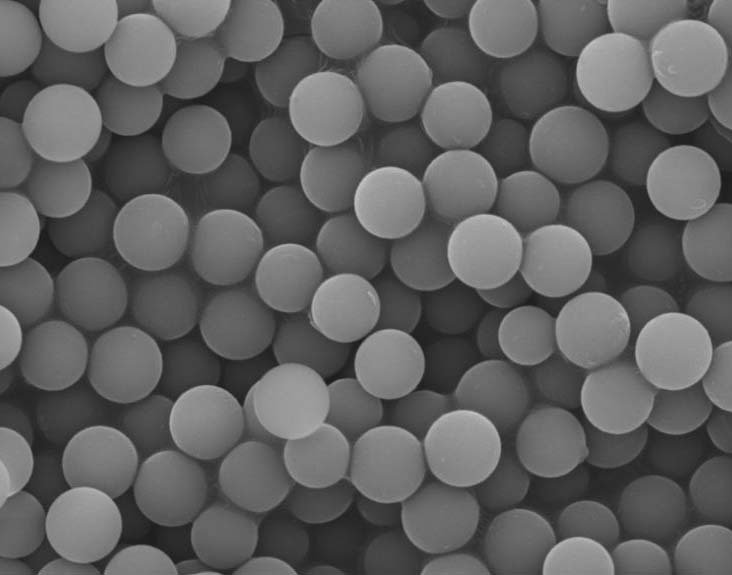

SEM analysis: the sample was soaked in liquid nitrogen for 10 min, and the brittle fracture was removed directly. After the surface was treated with gold spray, the sample was treated by SEM MX-180, MX-300, MX-1000, MX-1500, MX-2000.

(the corresponding microspheres are replaced by their models below), with a refractive index of 1.49.

1. 2 instruments and equipment.

Co-directional twin-screw extruder, SHJ-35, China Guanda rubber plastic machine.

Machinery Factory; injection Molding Machine, HY600, Ningbo Haiying Plastic Machinery Co., Ltd. UV-visible spectrometer, UV-2450, UV spectrometer integrating sphere, ISR-2200, scanning electron micromirror (S E M), J S M-6360L A, Japan Shimadzu Co. Microcomputer controlled electric universal testing machine, W D T-10, Shenzhen Kai Qiangli Machinery Co., Ltd.; impact testing machine, XJU-22, Chengde testing Machine Factory.

1. 3 sample preparation.

Pure PC was dried at 110 °C for 12 h, and then double.

The screw extruder is mixed with different particle sizes of light diffuser to produce 10% masterbatch of light diffuser, and then the masterbatch is mixed with PC in a certain proportion, and the injection molded light diffusion plate with 1.5% mass fraction of light diffuser is prepared by injection molding mechanism.

1. 4 sexual ability test.

According to GB/T 2410 Mel 2008, it is measured in the visible band.

The light transmittance (T t) and the light transmittance (T d) at which the light line deviates from the original incident light line 2.5 °, the haze is calculated to be TD / T t.

SEM analysis: the sample was immersed in liquid nitrogen to soak 10min, and the brittle fracture was removed directly. After the cross-section was treated with gold spray, the dispersion of light diffuser in PC light diffusion plate was observed on SEM.

Mechanical property test, tensile strength test according to GB/T1040.1-2006b

2. 2 the study of the mechanism of optical diffusion can be seen from the 2.1 microscopic morphology that the light is folded after the incident.

There are three types of shooting:

1) refraction occurs when the incident light enters the PC substrate.

2) the incident light line generates refraction at the hole.

3) the incident light line is refracted with the light diffuser. When the pore decreases until it disappears, the light enters the PC and refracts.

2) the incident light is refracted with the light diffuser.

The refractive indices of PC, air and light diffuser crosslinked PMMA microspheres are 1.59 and 1.00 respectively. So the annual refraction diagram of light in PC light diffusion material in China is shown in figure

2. According to the definition of haze, it is the percentage of the ratio of the scattered luminous flux of 2.5 heavy rain to the luminous flux passing through the material that deviates part of the parallel light from the incident direction, so the more times the light is refracted in the substrate, the greater the haze in theory. According to the light diffusion refraction diagram shown in figure 2, when there are pores in the light diffusion material, the number of light refraction is more than that in the light diffusion material without pores, and because the larger the particle size, the smaller the ratio of the pore diameter to the diameter of the light diffuser, so it is speculated that when the particle size of the light diffuser increases, the haze of the light diffusion material decreases.

Because the particle size of the light diffuser used in this experiment is 1.8 ~ 20.0 μ m, and its size is larger than the visible wavelength, so its light diffusion effect belongs to Mie scattering. According to the Mie scattering law, the spherical particles are uniformly dispersed in the matrix resin, and the scattered light intensity of the system is the total light transmittance, which is a function of the refractive index, particle size, scattering angle, and wavelength of incident light in the medium around the particles [2]. Because the scattering angle and the wavelength of incident light in the medium around the particles are certain, when only considering the effects of refractive index and particle size on the optical properties of the sample, in a certain range, the larger the particle size is, the larger the difference of refractive index is, and the scattered light intensity of the sample is higher. therefore, in a certain range, it is speculated that the light transmittance increases with the increase of particle size.

According to the light diffusion mechanism, when the light diffuser forms a two-phase structure with the PC substrate, it can be obtained by changing the particle size of the light diffuser. Change the porosity between it and the PC substrate, so do not consider increasing PC.

Compatibility between the substrate and cross-linked PMMA microsphere light diffuser. 2.3 effect of particle size of light diffuser on optical properties of PC light diffusion plate 2.3. 1 shadow response to haze.

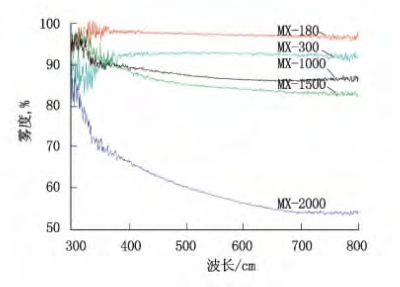

Figure 3 shows that the mass fraction of light diffuser is 1.5%. The injection color plate with different particle size is selected for UV spectrometer test, and the result is within the visible wavelength range (390 ~).

(780 nm), the haze curve of PC optical diffusion plate was filled with different particle size of optical diffuser. As can be seen from figure 3, with the increase of the particle size of the light diffuser, the haze of the PC light diffusion plate decreases.

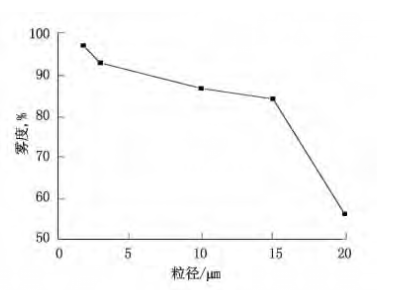

Figure 4 shows the effect of particle size on the haze of PC optical expansion plate when the 600nm wavelength in figure 3 is selected.

As can be seen from figure 4, the light transmittance decreases with the increase of particle size.

The maximum value was reached when the particle diameter was 1.8 μ m, and the haze was 92.89%. 2. 3. 2 shadow response to light transmittance.

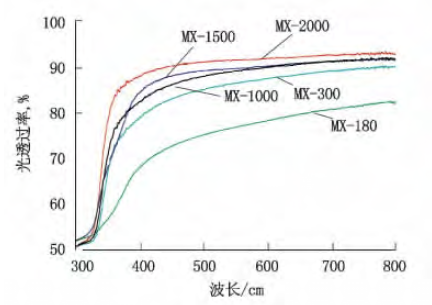

Figure 5 shows that the mass fraction of light diffuser is 1.5%. The injection color plate with different particle size is selected for UV spectrometer test, and the light transmittance curve of PC light diffuser plate is filled with different particle size light diffuser within the visible wavelength range (390 ~ 780 nm). It can be seen from figure 5 that the light transmittance increases with the increase of the particle size of the light diffuser.

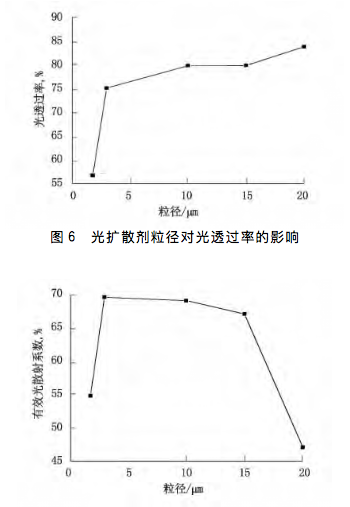

Figure 6 shows the effect of the particle size of the light diffuser on the light transmittance of the PC light diffuser when the 600nm wavelength in figure 5 is selected. It can be seen from figure 6 that the light transmittance increases with the increase of the particle size, and reaches the maximum when the particle diameter is 20.0 μ m, and the light transmittance is 83.73%.

2. 3. 3. Judging by the effective light scattering coefficient, the better particle size of the light diffuser can be seen from the practical application of the light diffusion plate, the light diffusion material needs to meet the requirements of high light transmittance and high haze at the same time. Therefore, the product of haze and light transmittance, that is, the effective light scattering coefficient, is introduced as a physical quantity to judge the light diffusion performance of the light scattering plate. Figure 7 is under the wavelength 600nm, multiplying the light transmittance and haze to obtain the relationship between the effective light scattering coefficient with the increase of the particle size of the light diffuser (1.5% of the mass fraction of the light diffuser).

As can be seen from figure 7, with the increase of the particle size of the light diffuser, the effective light scattering coefficient first increases and then decreases, reaching the maximum value of 69.68% when the particle diameter is 3.0 μ m. That is to say, the PC optical diffusion plate filled with 3.0 μ m optical diffuser can meet the requirements of both high light transmittance and high haze. At this time, the light transmittance is 75.01%, and the haze is 92.89%.

2.4 effect of Particle size of Optical diffuser on Mechanical Properties of PC Optical Diffusion Plate.

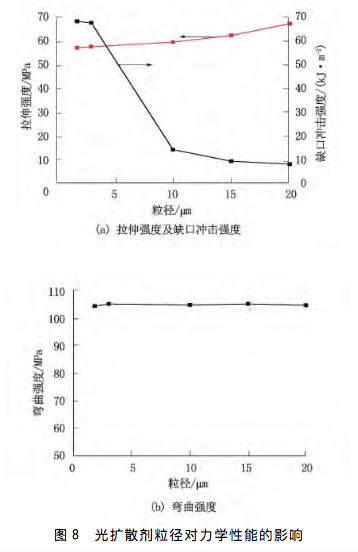

In the process of practical use, the optical diffusion plate must not only have good optical properties, but also meet the requirements of tensile strength, impact strength and bending strength in terms of mechanical properties. Figure 8 shows that the mass fraction of light diffuser is 1.5%, which is filled with light diffuser with different particle size.

2015 MODERN PLASTICS PROCESSING AND APPLICATIONS 27 (1).

Fig. 8 effect of particle size of light diffuser on mechanical properties.

A) the mechanism of the diffusion light source of PC light diffusion plate is that the incident light refracts and reflects when it passes through the PC substrate, pores and light diffuser. The curve of mechanical properties of PC light diffusion plate. As can be seen from figure 8, with the increase of the particle size of the light dispersant, the tensile strength of the PC light diffuser plate.

When the grain size is 20.0 μ m, the maximum tensile strength is 67.69 MPa. With the increase of the particle size of the light diffuser, the notched impact strength is basically unchanged when the particle size of the light diffuser is 3.0 μ m or less, and when the particle size continues to increase, the notched impact strength decreases.

Hurry up. With the increase of the particle size of the light diffuser, the bending strength is basically unchanged. This is because the content of light diffuser added in this experiment is less, which is not enough to cause obvious changes in bending properties.

The tensile strength, notch impact strength and bending strength of the optical diffusion plate are 55.00 MPa, 60.00 kJ/m2, and 100.0 MPa, respectively. The tensile strength, notch impact strength and bending strength of the light diffuser are 57.99 MPa, 68.13 kJ/ m2, and 105.2 MPa, respectively, which meet the requirements of the mechanical properties of the light diffuser.

2.4 effect of Particle size of Optical diffuser on Mechanical Properties of PC Optical Diffusion Plate.

In the process of practical use, the optical diffusion plate must not only have good optical properties, but also meet the requirements of tensile strength, impact strength and bending strength in terms of mechanical properties. Figure 8 shows that the mass fraction of photodiffuser is 1.5%. The effect of particle size on mechanical properties of photodiffuser filled with different particle size of photodiffuser in 2015 MODERN PLASTICS PROCESSING AND APPLICATIONS 27 (1) Fig.8.

A) the mechanism of the diffusion light source of PC light diffusion plate is that the incident light refracts and reflects when it passes through the PC substrate, pores and light diffuser. The curve of mechanical properties of PC light diffusion plate.

It can be seen from figure 8 that with the increase of the particle size of the photodispersant, the tensile strength of the PC photodiffusion plate increases gradually, and the maximum tensile strength is 67.69 MPa when the particle diameter is 20.0 μ m. With the increase of the particle size of the photodiffuser, the notched impact strength is basically unchanged when the particle size of the photodiffuser is 3.0 μ m or less, and decreases rapidly when the particle size continues to increase. With the increase of the particle size of the photodiffuser, the bending strength is basically unchanged.

This is because the content of light diffuser added in this experiment is less, which is not enough to cause obvious changes in bending properties. The tensile strength, notch impact strength and bending strength of the optical diffusion plate are 55.00 MPa, 60.00 kJ/m2 and 100.0 MPa, respectively. The tensile strength, notch impact strength and bending strength of the photodiffuser are 57.99 MPa, 68.13 kJ/ m2 and 105.2 MPa, respectively, which meet the requirements of the mechanical properties of the light diffuser.

3 conclusion.

A) the mechanism of the diffusion light source of PC light diffusion plate is that the incident light refracts and reflects when it passes through the PC substrate, pores and light diffuser.

B) with the increase of the particle size of the light diffuser, the light transmittance of the PC light diffusion plate increases and the fog decreases, when the particle diameter is 20.0 μ m, the light transmittance is 83.73%, and when the particle diameter is 1.8 μ m, the fog is 92.89%.

C) when the particle diameter of the light diffuser is 3.0m, the PC light diffusion plate with light transmittance and high haze can be obtained, and the prepared PC light diffusion plate can meet the requirements of mechanical properties.