Uniform dispersion of light diffusing agent, unstable optical performance in the preparation of the light diffusing polcarbonate(PC) material, use a multi-scale complex and masterbatch technology to improve dispersion and compatibility of light diffusion agent in the PC, improved optical performance of light diffusion composite material. This work systematically studied the preparation conditions of light diffusion masterbatch, using transmittance/haze tester, scanning electron microscopy, transmission electron microscopy and differential scanning calorimetry testing optical properties, structure and morphology, thermal and other properties of the light diffusion composites, study the effects of the optical, mechanical, thermal system to improve the content of the light diffusion agent, the different processing and various concentrations of masterbatch, the results show that masterbatch filling technology is an effective solution to the light diffusing agent disperse difficulty in the PC,Unstable of the optical properties. The main contents are as follows:

- Using masterbatch filling method propared three kinds of light diffusing masterbatch. By the burning residual experiment of masterbatch, Identifying the light diffusing agent of MKMP590, MPMMA content and MTio2 are 9.74wt%, 9.56wt%, 9.46wt%, making the light diffusing agent of PC light diffusion material having a more accurate content.

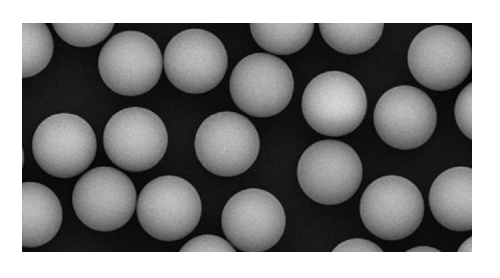

2. Using masterbatch filling technology researching the effect of composite optical, mechanical and thermodynamic properties through changing light diffusion agent content and types. PC and light diffusion agent mixed into the double screw extruder to give a concentration of 10%wt of the light diffusion masterbatch, then PC and light diffusion masterbatch mixed to prepare the light diffusing composites by melt compounding method, analyzing optical properties and microstructure of the samples. The results obtained: with the increasing of the light diffusing agent KMP590 content, the haze of the composite from 75% to 92% and the transmittance of the composite from 80% to 57%; with the increasing of the light diffusing agent PMMA content, the haze of the composite from 77% to 93% and the transmittance of the composite from 77% to 59%; When using a particular size of 2.2um of KMP590 light diffusion agent, the tensile and impact properties of the composites changed a little; when using a particular size of 3.0um of PMMA light diffusing agent, the tensile properties of the composites changed a little, but the impact properties of the composites changed from 70kJ/m2 to 18kJ/m2. SEM images observed: light-diffusing agent KMP590 and PMMA dispersed in light diffusion composite.

3. Using different processes preparing light diffusion composite, researching the effect of properties through using a different processes. The different process include: direct method, single screw masterbatch method, double screw masterbatch method. The results obtained: using the direct method, with the increasing of light diffusing gent content, the haze of the increased to 90.2% and the transmittance of the composite reduced to 56.5%, showing from repeated experiments data, directly added method process is unstable, deviations of the data is large, from 2.509% to 4.532%; showing from SEM of the composite, the light diffusion agent dispersed unevenly in PC。 Using the single screw masterbatch method, with the increasing of the light diffusing agent content, the haze of the increased to 91.8% and the transmittance of the composite reduced to 54.9%, showing from repeated experiments data, directly added method process is better, deviations of data is not large, from 0.992% to 3.542%; showing from SEM of the composite, the light diffusion agent dispersed unevenly in PC。 Using the double screw masterbatch method, with the increasing of the light diffusing agent content, the haze of the increased to 92.1% and the transmittance of the composite reduced to 57.2%, showing from repeated experiments data, directly added method process is stable, deviations of data is a little, from 0.265% to 2.490%; showing from SEM of the composite, the light diffusion agent dispersed unevenly in PC.

4. Using different concentrations of masterbatch preparing light diffusion composite, discuss the optical properties of composite materials prepared by different concentrations of masterbatch. PC and light diffusion agent mixed into the double screw extruder to prepare masterbatch of different concentrations filling( 10wt%, 20wt%, 30wt%,50wt%), PC and light diffusion masterbatch mixed into the double screw extruder to prepare the light diffusing composites by melt compounding method, the study of the optical properties and the deviation of repeated trials. The results obtained: the light diffusion composite what prepared by different concentrations of masterbatch all have excellent performance, deviation of repeat the test are small, deviation from 0.311% to 2.132%. However, during the preparation of the light diffusion masterbatch, loss of the light diffusing agent increases with the increasing of masterbatch concentration, using the masterabtch concentration of the 10wt% or 20wt% preparing the light diffusion composite is most appropriate.

Through the study of optical diffusion masterbatch and its application, we think that there are still some aspects in this field to further expand and deepen.

1. Try the combination of multiple light diffusers to coordinate the scattering effect in order to further improve the optical properties of the materials and reduce the cost.

2. The optical diffuser used to fill the modified PC can be properly modified to enhance the application effect by the scattering effect of the light diffusion agent